- Home

- About Us

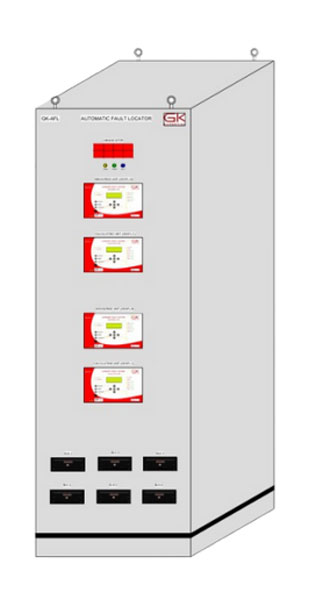

- Products

Numerical RElays

Control & RElay Panels

- Services

- Automation

- Sustainability

- Contact Us

- Home

- About Us

- Products

Numerical RElays

Control & RElay Panels

- Services

- Automation

- Sustainability

- Contact Us